Understanding the Stages and Significance of Refining Crude Oil

Petroleum Refining Exploration. Oils, petroleum products, chemicals, biofuels, and gasses play essential roles in our daily lives worldwide. Many of these essential substances originate from the complex process of refining petroleum. Petroleum refining, also known as oil refining, is a sophisticated procedure designed to separate various hydrocarbon fractions from unprocessed crude oil, commonly referred to as petroleum. This complex process involves five fundamental refining stages:

Petroleum Refining Exploration

1. Separation: Distillation and Absorption

Distillation and absorption methods are employed to isolate different hydrocarbon fractions.

2. Cracking: Breaking Down Large Molecules

Cracking involves the transformation of large hydrocarbon molecules into smaller ones.

3. Restructuring: Rearranging Molecular Structures

Restructuring requires the reconfiguration of molecular structures within the hydrocarbon compounds.

4. Combination: Creating Larger Molecules

Combining smaller hydrocarbon molecules to form larger ones is a critical step in the process.

5. Petroleum Refining Exploration. Treatment: Removing Contaminants

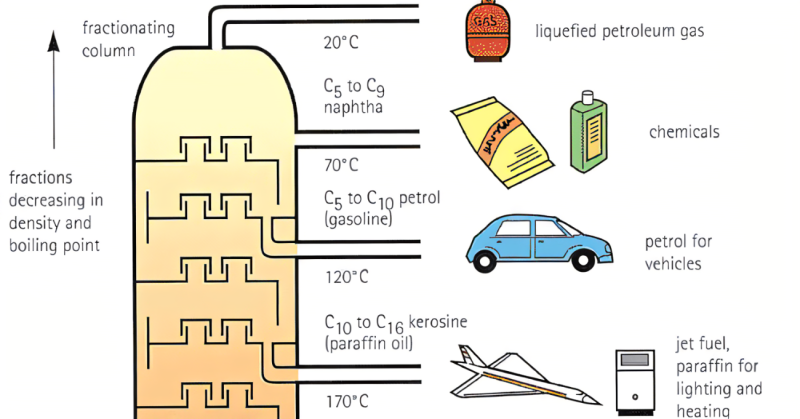

Chemical treatments are used to eliminate contaminants, such as sulfur, nitrogen, oxygen, water, dissolved metals, and inorganic salts, from the fractions. Hydrocarbon compounds contrast in their chain lengths, which results in varying boiling points; longer chains have higher boiling points. Refiners classify certain compounds known as fractions. The primary method for separating these fractions is fractional distillation, wherein crude oil is heated and boiled in a fractional distillation column. As the vapor ascends through the trays within the column, it gradually cools and condenses into a liquid. These liquid fractions are collected in trays and may experience further cooling in condensers before being transferred to storage tanks.

Only a select few components emerging from the fractional distillation column are market-ready. Many require additional chemical processing, such as restructuring and combining, to transform them into other useful fractions. Following distillation and chemical processing, these fractions experience treatment to eliminate impurities. This includes organic compounds containing sulfur, nitrogen, oxygen, water, dissolved metals, and inorganic salts. Once treated, the fractions are cooled and blended to produce a diverse range of products. These products are transported to terminals via vessels, pipelines, trains, or trucks.

Petroleum Refining Exploration. In essence, from crude oil to end products, the refining process depends on temperature differences within the fractional distillation column, with higher temperatures at the bottom and cooler conditions at the top.